Transformer oil is a liquid that is stable at high temperatures and has excellent electrical insulating properties. Typical motor oil that most people think of, is not the type of oil in a transformer. Transformer oil keeps the transformer cool. It also insulates the transformer and allows electrical components to be more compact than free air apparatus.

To improve the cooling process, radiators or “fins” are installed on the side of a transformer. The oil circulates through the transformer by natural convection. Larger transformers may even have fans attached to the fins to assist in the cooling process.

Why take oil samples?

Transformer oil can be similar to a window of a house. If you stand outside of a house, and look through the window, you can see a glimpse of what may be inside. That is the same for oil. While it may be extremely difficult to physically see inside of a metal tank, we can still analyze the oil and paint the picture of the inside.

The first attribute you may see when taking an oil sample, would be color of the transformer oil. Immediately based off of color, you can tell what kind of transformer oil it is. Mineral oil, Silicone oil, or FR3 are the most common oil types in my particular working area.

The specifications for all oil is different between each manufacturer, but they are all relatively the same when comparing the same oil types. Flash point is one of the driving factors of which type of oil is to be used. If you have to install a transformer in the basement of a building, 3 floors underground, you may decide you want a higher flash point depending if it is occupied office space.

Or if it is a parking garage, you may not care about flash point at all. If it is a government facility, they may mandate biodegradable. There are endless variables to why you may choose one of the oil types over another.

How do you take a transformer oil sample?

Taking a good oil sample is not a difficult task. Taking a bad oil sample is a very easy task. There is a lot of discussion about proper oil sampling techniques, but being in the field myself, most of these proper techniques are not achievable.

1. You need to know what fluid you are dealing with.

(Mineral oil, Silicone, FR3, etc.)

2. You need to identify what the specific gravity is of the oil.

(The specific gravity of water is 1.0. Does the oil have a specific gravity >1 or <1. If the oil has a specific gravity >1, this means the oil will settle to the bottom and any water or moisture will sit on top. You need to take your sample from the top. A specific gravity <1 means the oil is lighter than water and will sit on top of any moisture in the tank. You want to take your sample from the bottom.)

3. You need to have the proper tools to do the job.

(Adjustable crescent wrench, channel lock pliers, 3/8″ and 1/4″ tubing, empty sterile oil sample bottle and/or DGA syringe, rags, etc.)

4. Locate the transformer sample valve

5. Unscrew the cap, channel lock pliers may be necessary.

6. Loosen the smaller valve.

7. Attach 3/8″ hose and drain waste. Then fill a new container with the sample specimen.

8. Dissolved gas analysis sample should be taken after the general sample.

Transformer Oil Sampling Video

Do you need to de-energize the transformer before sampling?

This can be tricky. Most people will argue that you should de-energize the transformer before taking a sample. You need to verify that the transformer is not under a vacuum and/or has positive pressure on the pressure gauge.

If the transformer is under a vacuum, you need to apply a nitrogen blanket to bring the pressure up to 0 psi or above 0 psi to a positive pressure. Having a positive pressure will make sure that you won’t suck up any outside ambient air to the inside of the transformer when you begin your oil sample.

Different types of transformers warrant different things. If the transformer is a padmount style transformer that is 13,800V Primary and 480/277V or 208/120V, you may need to de-energize the transformer for safety reasons. Larger transformers in secured locations (behind a security fence) will have a valve on the bottom of the tank that is readily accessible.

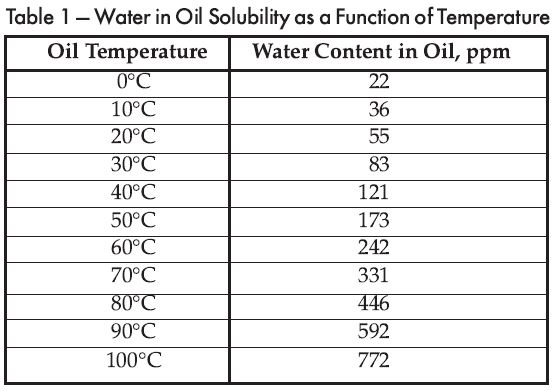

Use your best judgement on whether or not to de-energize. If you de-energize, make sure you take your oil sample while the transformer windings are still hot. The hotter the windings are, the more moisture content will be expelled from the windings into the oil. Transformer paper insulation absorbs moisture. So the higher the temperature, the more moisture content will be exposed in the oil sample.

Available oil types

1. Biodegradable (Envirotemp FR3, biotemp)

Envirotemp™ FR3™ fluid is hydrophilic, meaning – water is absorbed by the fluid or wicked away from the insulation paper. At room temperature, FR3 fluid has 10 times the water saturation level as mineral oil (FR3 fluid can dissolve over 1000 mg/kg of water before becoming saturated compared to 60 mg/kg for mineral oil at 20°C.)

These oils typically consist of raw vegetable oils. Usually whatever is available on the market at the time of manufacture. The most common oils include sunflower, safflower, and soybean oil. This is 100% edible and meets the U.S. Environmental Protection Agency (EPA) criteria for “Ultimate Biodegradability” classification.

2. Mineral oil

Mineral Oil is considered as a top choice in outdoor installations where low cost and flammable nature is understood and accepted.

3. Silicone oil

Silicone oil is a little less flammable than Mineral oil. It has a high fire point and is typically used in indoor areas like below grade transformer vaults. It can also be used for outdoor applications.

Key Thermal Properties:

| Mineral Oil | Silicone | Envirotemp® | |

|---|---|---|---|

| Fire Point | 165°C | 371°C | 360°C |

| Flash Point | 145°C | 268°C | 330°C |

What does a sample tell us?

Oil samples are the DNA to a transformer. There are key gasses that we look for in a Dissolved Gas Analysis (DGA). Acetylene, Hydrogen, Ethylene, Methane and Carbon Monoxide are a few we look out for.

Some of the tests performed are:

- Dielectric breakdown voltage: ASTM D 877 and/or ASTM D 1816

- Acid neutralization number: ANSI/ASTM D 974

- Specific gravity: ANSI/ASTM D 1298 (*Optional)

- Interfacial tension: ANSI/ASTM D 971

- Color: ANSI/ASTM D 1500

- Visual Condition: ASTM D 1524

- Water in insulating liquids: ASTM D 1533.

- Power factor or dissipation factor in accordance with ASTM D 924. (*Optional)

| Fault | Key Gas | Result |

|---|---|---|

| Arcing | Acetylene | large amounts of acetylene and hydrogen or minor quantities of methane and ethylene can be produced |

| Corona | Hydrogen | low energy discharges generate hydrogen and methane as well as minor quantities of ethane and ethylene |

| Overheated Oil | Ethylene & Methane | Overheating will produce ethylene and methane (300°F) or hydrogen and methane (1,112°F). Traces of acetylene may be formed if the fault is severe or involves electrical contacts. |

| Overheated Cellulose | Carbon Monoxide | f cellulose is overheated, carbon monoxide is generated. |

2 comments on “Transformer Oil – What is it, and why sample?”

Great site and information.

Thank you! Thanks for posting that link!